Marble Stone Coated Aluminum Honeycomb Panel for Curtain Wall Decorative with Stone Grain

Overview Product Parameters Detailed Photos Stone Honeycomb Panel is a fabricated stone panel wall cladding system utili

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | SHP |

| Level | A |

| Application | Interior Decoration |

| Weight | 22kg/M2(15mm Thickness) |

| Advantage | Light Weight/High Strength/Acoustic Insulation |

| Surface Treatment | Polished/ Antique/ Flamed/ Brushed |

| Thickness | 8-100mm, Can Be Customized |

| Transport Package | Protective Film on Surface and Plywood Crates |

| Specification | 300*600mm, other can be customized |

| Trademark | ALUCROWN |

| Origin | Foshan Guangdong, China |

| HS Code | 6802999000 |

| Production Capacity | 10000 Square Meters/Per Month |

Product Description

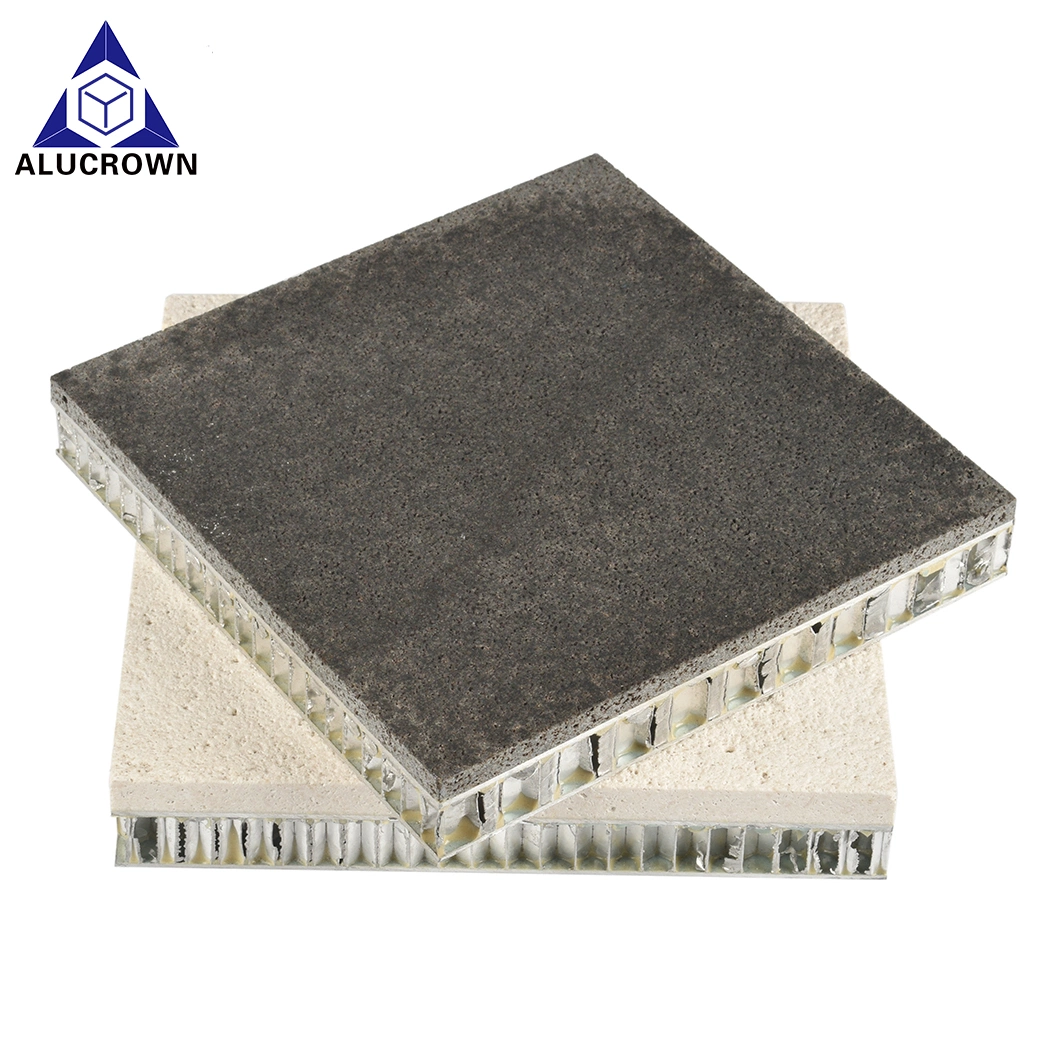

| Item Description | Natural stone Aluminum honeycomb panel | Photo |

| Composite | Natural stone + Glue + Porcelain/aluminum honeycomb panel base | |

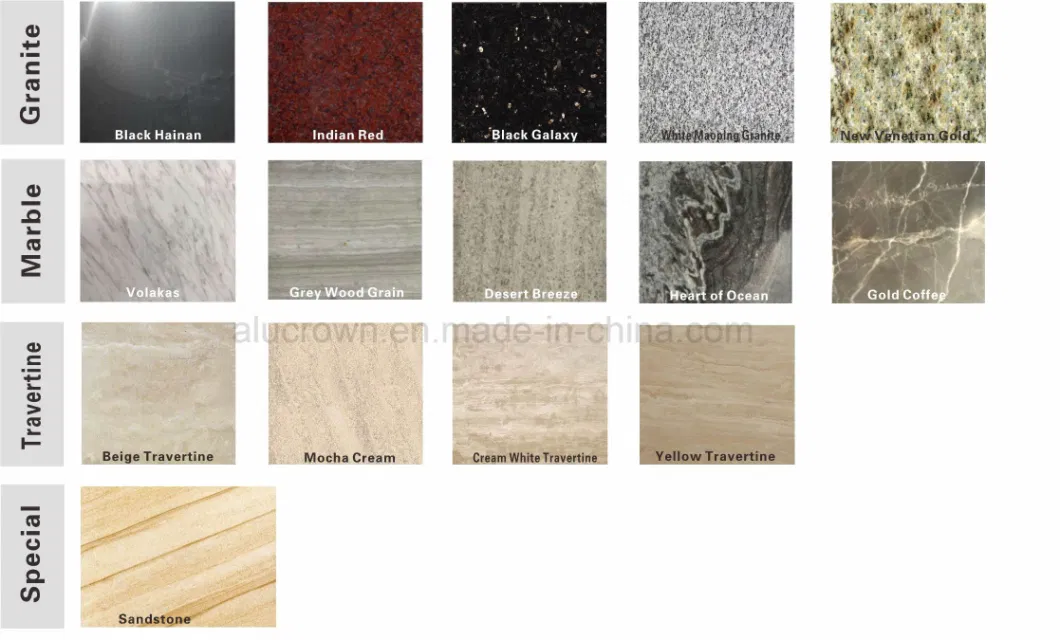

| Stone type | Marble, Granite, Sandstone, Limestone ,etc | |

| Stone Thickness | 3-5mm natural stone veneer | |

| Total thickness | 8-100mm, can be customized | |

| Surface | Polished/ antique/ flamed/ brushed | |

| Standard size | 300*300mm, 300*600mm,600*600mm,600*900mm,1200*2400mm, other can be customized | |

| Weight | 22kg/m2(15mm thickness) | |

| Application | Building wall decoration, floor, table, ship, etc | |

| Package | Protective film with foam and plywood crate |

Detailed Photos

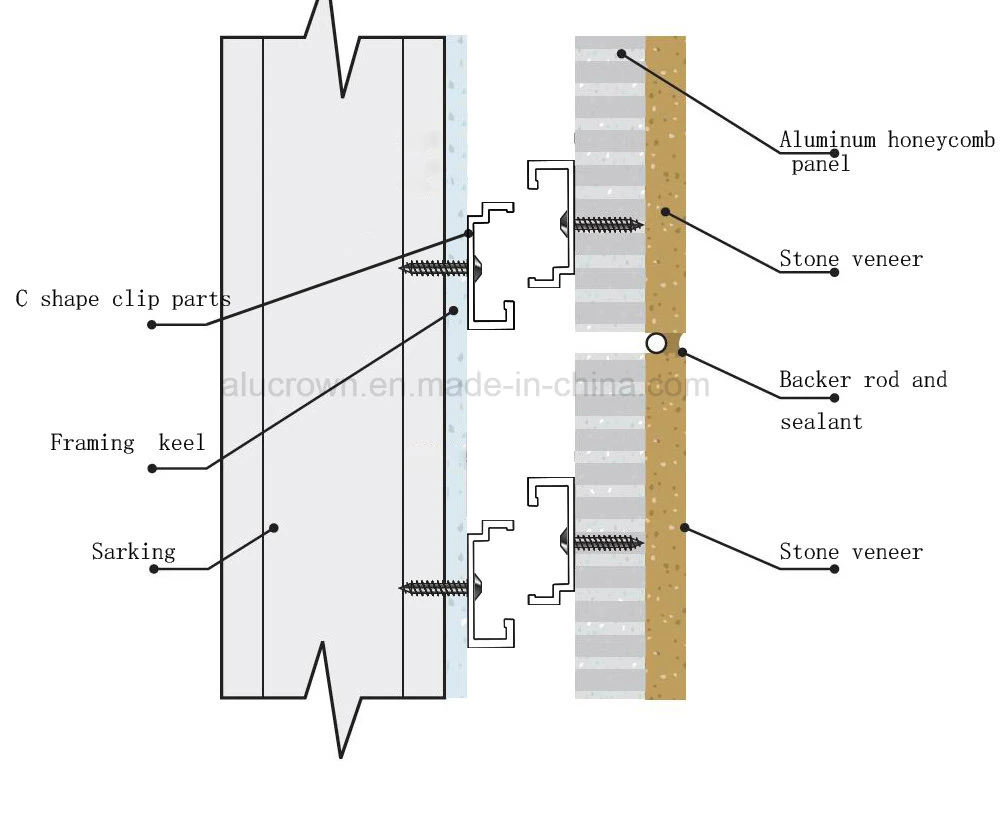

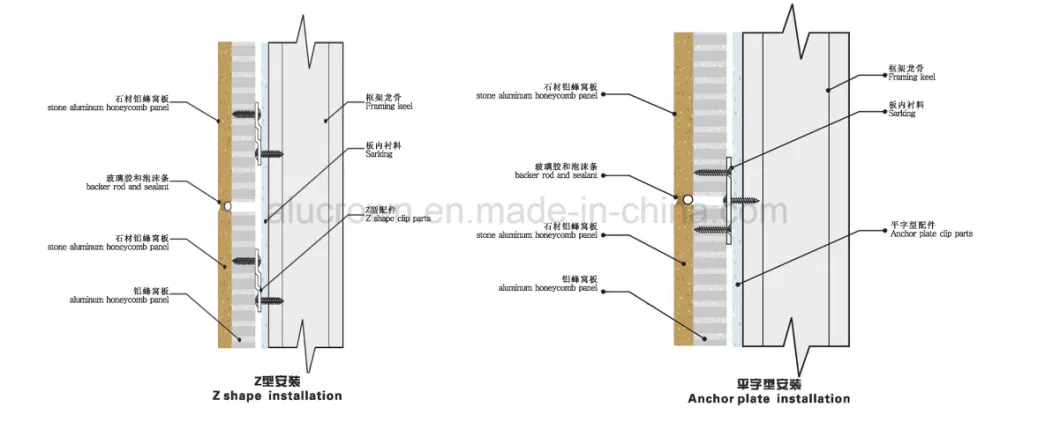

Stone Honeycomb Panel is a fabricated stone panel wall cladding system utilizing a composite panel made by laminating a natural stone layer to an aluminum honeycomb panel with aviation grade epoxies. Alucrownstone is fabricated and then attached to the wall with a series of aluminum extrusions. Alucrownstone can feature a large range of natural stone finishes, including granite, marble, limestone and sandstone. The natural stone composite panels are suitable for interior and exterior use, being highly weatherproof and suitable for high impact areas.

Stone honeycomb panel specificationFace sheet: 3-10mm natural stone veneerTotal thickness:10-35mmMaximum size: marble honeycomb panel 1500*3000mm, granite honeycomb panel 1200*2400mmGranite:5.74 pounds/sq.ft (28kg/sq.m), 1/2 weight of 2cm granite slabMarble: 5.33 pounds/sq.ft (26kg/sq.m), 1/2 weight of 2cm marble slabSpecial size & shape: can be customized according to project's drawing

More Finish Option

Disclaimer: Please note stone is a natural product. As a result, no two pieces are identical and may vary in markings, colour and texture. In some stones it is common to find spots, fossils or shelly formations, pit holes, open texture streaks, iron spots, and grain formation changes.

TECHNICAL DATA

| NO. | ITEM | STANDARD | TESTED VALUE | RESULT |

| 1 | Flat Bonding Strength | Average ≥ 1.0 MPa;Minimum ≥ 0.6 MPa | Average 1.31 MPa;Minimum 0.88 MPa | Pass |

| 2 | Flat Tensile Strength | ≥ 0.8 MPa | 0.91 MPa | Pass |

| 3 | Flat Tensile Modulus | ≥ 30 MPa | 70.7 MPa | Pass |

| 4 | Flat Shearing Strength | ≥ 0.5 MPa | 0.54 MPa | Pass |

| 5 | Flat Shearing Modulus | ≥ 4.0 MPa | 6.43 MPa | Pass |

| 6 | Bending Strength | ≥ 8.0 MPa | 41.0 MPa | Pass |

| 7 | Bending Rigidity | ≥ 1.0 x 10^9 N.mm^2 | 2.86 x 10^9 N.mm^2 | Pass |

| 8 | Shearing Rigidity | ≥ 1.0 x 10^5 N | 4.40 x 10^5 N | Pass |

| 9 | Climbing Drum Peel Strength | Average ≥ 50N.mm/mm;Minimum ≥ 40N.mm/mm | Average 9.1N.mm/mm;Minimum 42.4NN.mm/mm | Pass |

| 10 | Fasten Fitter Loading Capacity | ≥ 3.2 kN | 3.2 kN | Pass |

Our Advantages

Why use Crownstone over traditional solid stone??

1.Lightweight-Crownstone is only 1/5 of the weight of its equivalent in traditional stone. This means that the product is much easier to handle and to ship, lessening damages, and improving onsite efficiency and safety.2,Simpls installation-Crownstone offers far improved attachment over traditional solid stone. The solid stone anchoring system exposes the weakest properties of the stone, whereas the fixing systems offered with Crownstone are rapid and align with common systems already used in Australia.3,Flexibility-Alucrown panels, using stone as a veneer over the honeycomb core are much flexible than dimensional stone. As a result the panels are much less prone to fracturing and cracking and better able to withstand building movement and extreme weather events.4,Stability-The thin stone found on Alucrown panels lack the torsional force the thicker traditional stone. This means the lightweight Alucrown systems doesn't experience the stability failure that occurs in traditional stone.MANUFACTURING QUALITY

A dedication to the total fulfillment of our client's and customer's expectations is reflected by a complete quality control system, beginning at the point of specification and continuing through to delivery of the guaranteed products. All activities are carried out in a manner which:1,Uses the framework of ISO9000 Quality Standards to verify the quality of our systems2,Ensures that our products and services are of the highest standards3,Creates continuous improvements to our product through the application of the best quality practices.

WARRANTY

The standard warranty(Exterior wall) is 15 years

Factory

Application

Packaging & Shipping

Packing with protective film and plywood crate

FAQ

FAQ:

Q:Are you trading company or manufacture?

A: We are a manufacturing company with both a factory and foreign trade capabilities, enabling us to offer customers more competitive prices

Q:Why do clients choose us?

A:Clients choose us because we have 10 years of experience producing aluminum cladding panels and a professional team that provides end-to -end serivice, offering better solutions for any project problems our clients may encounter.

Q: How did you test the product before they are packed?

A :We have the strict QC procedure , each product will be tested by three times with professional machine before packing.

Q:How long is your delivery time?

A: Usually it takes 20-25 days after receiving deposite

Q:Could I get some samples? Do I have pay for them or just cover the shipping cost?

A: Sure, we offer free samples. But you'll need to take care of the shipping fee

Q:What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment >=1000USD, 30% T/T in advance, balance before shippment or LC at sight.

Related Products

-

![Natural/artificial floor/wall/cladding/building/paving/cube/kerb/loose polished/antique/flamed/honed marble/granite/quartz/travertine/onyx Stone for decoration]()

Natural/artificial floor/wall/cladding/building/paving/cube/kerb/loose polished/antique/flamed/honed marble/granite/quartz/travertine/onyx Stone for decoration

-

![Outdoor Indoor Decorative Building Pillar Natural Stone Greek Column Marble Roman Columns for House]()

Outdoor Indoor Decorative Building Pillar Natural Stone Greek Column Marble Roman Columns for House

-

![Garden Home Architectural Decorative Carved Stone Roman Pillars Marble Carving Greek Tapered Column for Indoor Outdoor Decoration]()

Garden Home Architectural Decorative Carved Stone Roman Pillars Marble Carving Greek Tapered Column for Indoor Outdoor Decoration

-

![Golden Yellow/Green/White Quartz Slate Flagstone Mat Mesh Stone Tile]()

Golden Yellow/Green/White Quartz Slate Flagstone Mat Mesh Stone Tile